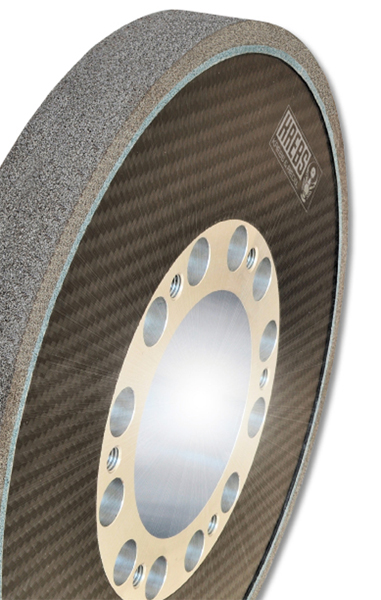

Top high-precision grinding of hard iron and steel alloys or hard and brittle materials, the best removal rates and the longest service life are still provided by the hardest materials in the world: CBN and diamond.

Cubic boron nitride, CBN for short, is particularly suited to difficult to machine or high-alloyed hardened steels with a hardness of 54 HRC or more such as high-speed steel, tool or chrome steel, nickel-based alloys, powder metallurgy steels or white cast iron.